In 2022, the global market for frozen baked goods reached $23.43 billion. According to forecasts, by 2030 it will grow to $35.98 billion, with an average annual growth rate of 6.2% (Data Bridge Market Research, 2023). This figure speaks for itself: frozen puff pastry products have firmly established themselves in the product range of bakeries, retail chains, and the HoReCa segment.

It would seem that everything is simple: defrost a croissant, put it in the oven, and you get a freshly baked, fragrant pastry. But in practice, the result does not always meet expectations. The dough loses volume, the layers stick together, and instead of a crispy masterpiece of French gastronomy, the finished product turns into a dense, quickly stale product with a crumbly texture. Why does this happen? And how can these mistakes be avoided? The answer begins with the main ingredient of any dough: flour.

The croissant has become a symbol of French baking culture. But its history has its roots in Vienna, from where it came to France. Today, croissants and Danish pastries are in demand all over the world.

The market for frozen semi-finished products is growing rapidly, allowing bakeries and retailers to offer fresh products with minimal effort. This means higher requirements for product quality stability after freezing and thawing.

The problem starts with the grain

The quality of flour reflects the quality of the grain.

Millers around the world are facing a shortage of high-protein wheat. There are increasing reports of batches with reduced protein content and extremely low specific weight. The reasons lie in soil depletion, climate change, and poor agricultural practices. For example:

– Eastern Europe is experiencing a shortage of high-protein wheat due to dry conditions and depleted soils.

– In Western Europe, on the other hand, the harvest has been affected by excessive rainfall, resulting in low falling numbers (FN), which directly affect flour quality.

In 2023, the average FT of wheat grain in a number of European regions fell below 350 seconds. This is critical for puff pastry products: low grain FT negatively affects the rheology of puff pastry and the quality of the final product.

However, the opposite situation is also dangerous. In regions with arid climates, where the FT is above 500 seconds, flour exhibits low enzymatic activity, which impairs proofing and rising of the dough after thawing. The optimal WP for flour intended for frozen puff pastry semi-finished products is 380 seconds or higher with moderate amylolytic activity.

Even complex grain can give good results if its potential is properly revealed during milling and the negative impact on the rheology of the flour is minimized.

Problem grains produce flour with poor rheology. It is during milling that the potential of future baked goods can be realized.

How does milling affect baking?

With the development of milling technology, there has been a growing trend toward high flour extraction, i.e., the desire to extract more of the valuable endosperm. To achieve this, harsh milling conditions and entolators are used. However, there is a downside to these approaches.

Under aggressive mechanical stress:

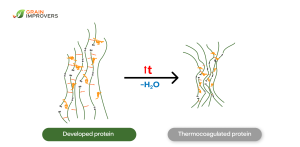

– Proteins coagulate and compact on the rollers due to heat and friction; in simple terms, they “bake.” Thermocoagulated protein loses its ability to swell and stretch (see Fig. 1), the gluten index decreases, and when washed, such gluten crumbles badly, resulting in poor dough rheology and baked goods.

Fig. 1. Protein after thermal coagulation on rollers

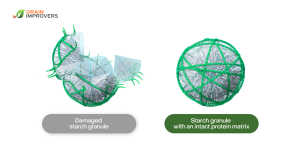

– Starch granules are destroyed, losing their natural 3D structure (see Fig. 2)

Fig. 2. Intact and destroyed starch granule

– An excess of fine fractions (particles less than 100 μm) appears in the flour, sometimes up to 70% of the total volume.

– Protein losses from grain to flour are up to 1.5% in old mills and from 1.5% to 3% in new mills with entolators.

Even when technological measures are observed — control of gaps and cooling of rollers — in some regions, protein losses during milling remain an insurmountable problem due to the characteristics of the grain itself.

Croissant manufacturers working with finely ground flour encounter a number of defects:

– Damaged starch granules absorb a lot of water in a short period of time (at the mixing stage) but are unable to retain water during cutting and layering. This results in stickiness and a high percentage of trimmings and rejects.

– Destroyed starch particles actively absorb margarine/oil, causing fat to migrate into the dough and impairing the formation of layers.

– During freezing, a large number of ice crystals form, which further damage the protein-starch structure.

All these defects will have a negative effect on the growth of microcracks during freezing, thawing, and baking.

Let’s take a closer look at the two main problems in grain milling that affect the quality of the final product — croissants.

Problem 1. Very finely ground flour

In countries where low price and high flour yield are priorities, and flour quality is assessed by its lightness — for example, in India and a number of other regions in Asia and the Middle East — flour is traditionally produced with a very fine grind. This allows the price to be reduced by increasing the flour yield, but this approach to milling has serious consequences for the quality and quantity of baked goods, especially puff pastries.

If the proportion of fine flour (particles less than 100 µm) exceeds 50% and the falling number (FN) of the grain is below 350 seconds, such flour can be considered unsuitable for puff pastry.

Problem 2. Milling soft and low-protein wheat

When there is a shortage of high-protein wheat and soft wheat with low protein content is used for milling, it is very important to monitor the particle size distribution of the flour and avoid protein thermal coagulation on the rollers, as well as excessive destruction on the entoleators. Soft wheat should also not be mixed with harder wheat in the milling batch to increase the total protein content. This exacerbates protein defects during milling.

How problems with flour can be seen on instruments

When testing on instruments such as an alveograph and a farinograph, we obtain the following data:

– Elevated P values (elasticity) — due to thermal coagulation of protein that has lost its elasticity.

– Low L values (extensibility) — the dough does not stretch well and begins to tear.

– Low G values — evidence of gluten network destruction.

– High P/L ratio — imbalance between elasticity and extensibility leads to tears and breaks in the dough during cutting.

– Low stability and significant liquefaction according to the farinograph — the dough does not retain moisture and quickly loses stability.

The problem of superfine flour from soft wheat can be exacerbated by the high availability of broken starch to the action of the grain’s own amylases (at a falling number of less than 330 seconds). When kneading dough from superfine flour, grain amylases excessively hydrolyze starch, forming dextrins and sugars, which makes the dough sticky and unstable. The main task of the baker is to prevent hydrolysis — the destruction of starch before freezing. This is the main conflict between the miller and the baker.

Such defects are critical for the production of puff pastries. They affect not only the appearance and taste of the product, but also the economic efficiency of production: the percentage of rejects increases, the yield of finished products decreases, and the number of customer complaints increases.

Solution: flour that works for results

Traditionally, flour made from high- or medium-hard wheat with a protein content of 12–16% is used to make croissants. It is this level of protein that gives the dough its optimal properties: elasticity, strength, and the ability to form an airy, layered structure after baking.

However, with the market increasingly facing a shortage of high-protein grain, meeting this standard is becoming a challenge. To obtain flour with the required protein level, manufacturers have to purchase more expensive raw materials and carefully select the milling batch.

This is where GRAIN IMPROVERS Smart (GI Smart) technology comes in. Enzymatic preparation of grain for milling and gentle milling modes expand the choice of raw materials for flour production. Thanks to this technology, mills can produce high-quality flour for puff pastries even from grain that was previously considered unsuitable for this product. For example, soft wheat varieties with low protein content and a falling number of 280 seconds can be used effectively, and excessive grinding of the grain can be avoided.

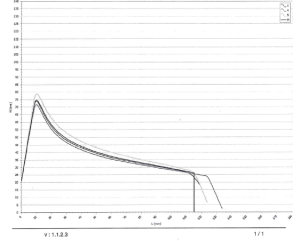

Fig. 3. Alveogram of flour suitable for frozen puff pastry

Temperature

Water: 19.4 °C

Dough mixer: 24.2 °C

Proofing chamber: 25.1 °C

Alveograph compartment: 20.7 °C

Parameters

Air humidity: 63.7%

Moisture content: 15%

Hydration: 50%

Base humidity: 15% H₂O

Water amount: 125 ml

Flour weight: 250 g

Standard Results

P: 82 mmH₂O

L: 114 mm

G: 23.7

W: 312 × 10⁻⁴ J

P/L: 0.72

Ie: 69.2%

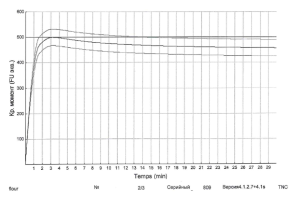

Fig. 4. Farinogram of flour suitable for frozen puff pastry

Chopin S:

Water absorption – 58.9%

Dough development time – 3.2 minutes

Stability – 12.9 minutes

Softening (FU equivalent) – 33 UF

MTI (Mixing Tolerance Index) – 48 UF

Cmax (FU equivalent) – 500 UF

We use different grain improvers, each of which addresses a specific problem and provides the desired effect.

How does enzymatic preparation of grain for milling work?

The valuable endosperm from which flour is obtained is protected by two layers of husks and an aleurone layer. The husks and aleurone layer are not needed in flour. However, they are firmly bound to the endosperm and are very difficult to separate during the milling process.

Therefore, it is important for every miller to remove the husks as much as possible before grinding so that they do not contaminate the flour and impair its baking properties. Only GRAIN IMPROVERS removes the husks while the grain is still wet during preparation for grinding. After passing through the husking and peeling machines, the grain is as free as possible from husks before grinding. This makes grain processing easier, more accurate, and more controllable.

The result is clean flour that retains valuable nutrients, vitamins, and minerals, ensuring high nutritional value and improved baking properties.

Enzymatic preparation of grain for milling with GRAIN IMPROVERS:

– Retains 0.5 to 1.5% protein during milling from grain to flour.

– Allows for increased flour yield without aggressive mechanical action.

– Reduces the number of passes between the rollers, minimizing protein thermocoagulation.

– Preserves the natural 3D structure of starch granules in an individual protein network.

As a result, the flour:

✔ Retains moisture better, reducing ice crystal growth during freezing.

✔ Has lower starch attack by its own grain amylases if the HP is low enough.

✔ Ensures dough stability during rolling and proofing.

✔ Preserves dough elasticity and plasticity during shaping.

✔ Provides high-quality proofing and stable rise after thawing.

Enzymatic preparation of grain for milling with GRAIN IMPROVERS allows you to achieve the desired rheological characteristics of flour without having to purchase grain at inflated prices. This approach guarantees stable flour quality and, therefore, croissants that are as close as possible to classic French standards in terms of texture and taste (Fig. 5).

Fig. 5. Perfect layering in a defrosted croissant

If you have limited quantities of high-protein grain at your disposal and the falling number (FN) is less than 350 seconds, this is no reason to abandon your plans to produce high-quality flour for layered baked goods.

At the same time, there are regions where flour has an insufficient level of broken starch, which also negatively affects the quality of dough and baked goods. In our experience, the reason most often lies in the raw materials — for example, in the characteristics of the milling mixture or the types of wheat used.

We are ready to conduct an analysis and offer individual recommendations that will help you adjust the parameters and achieve stable results.

We are confident that it is possible to achieve high-quality baked goods — all you need to do is unlock the biological potential of the grain and manage it at every stage of production. We invite you to discuss the details and find an effective solution together.