Biotechnologies that make profit to surge up to 21% and improves quality of grain mill products

Cheaper grain in the milling blend simultaneously enhancing flour parameters

Visible results right away:

Lowers energy consumption and machinery wearout up to 35% due to more gentle grinding

Every batch of flour meets the standards of the most demanding customers through ensuring manageable and stable result

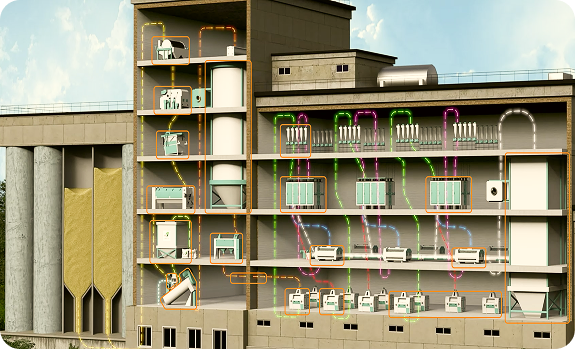

Revealing the essence of the grain and improving results on each consecutive step of production.

We are proud that it is a considerable advance for both output and quality of flour.

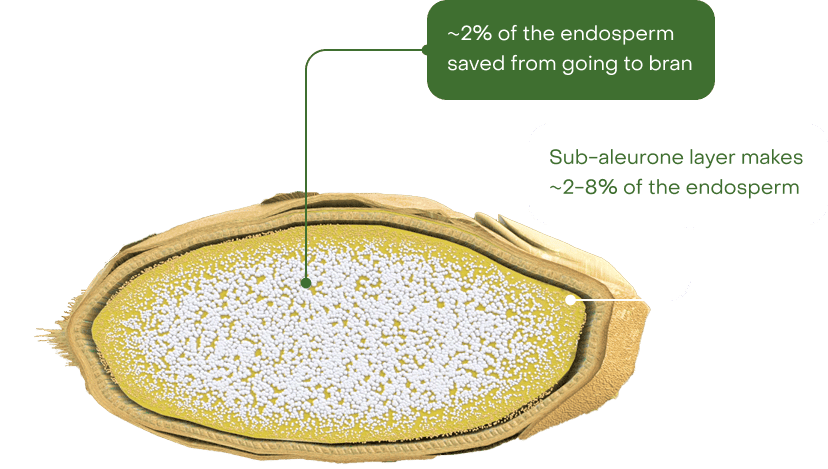

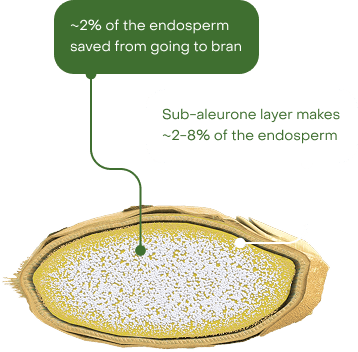

Grain Improvers technology increases the efficiency of grain conditioning by enzyme composition that tears the shell of grain while preserving the sub-aleurone layer rich in protein and vitamins.

The proportion of ash in flour is lower by 0.05-0.1%

Protein quality and quantity grows by 0.1-0.5% in final product

Natural increase in color: yellowness, lightness, whiteness

Dough rheology and consequently bread quality is higher and does not require flour additives. It is accomplished through change of gluten content and characteristics, flour particle size, and optimizing starch damage.

Fewer bran inclusions in pasta, ash content in flour is lower by 0,05-0,1%.

Protein quality and quantity grows by 0.1-0.5% in final product

Natural increase in yellowness (b) by +1-3 points and lightness (L) by +2-5 units. Reduction of gray pigment content.

The enzymatic composition positively reflects on the dough rheology, especially on its strength, elasticity and extensibility. This is due to granulometric composition, the moisture-retaining ability of the dough and growth of protein amount.

Increasing the yield of semolina by 3-6%

More valuable protein is collected around the germ, which gives additional +0.5% protein in each batch.

+1.5% more starch is preserved, preventing its loss during the production process.

Further processing of starch will be easier, since we get a cleaner product without any signs of contamination.

More valuable elements of the grain are saved for subsequent processing and utilization. And furthermore, it decreases the pollution of sewage and waste.

Thanks to corn moisture stabilization, presses need less strain for production and the manufacturing process becomes reliable. As a result, production outcomes become more predictable.

Our tests show a remarkable decline in the falling number of rye and triticale. For rye the parameter reaches the bottom at over 35% and for triticale it is up to 27%, which helps to improve the quality of the final product.

Final products contain less chemicals, and the proportion of ash in each batch goes down.

The enzymatic composition carefully saves crucial elements of grains, which leads to the dough rheology improvement

The mill’s energy consumption is optimized, contributing to both production sustainability and cost reduction

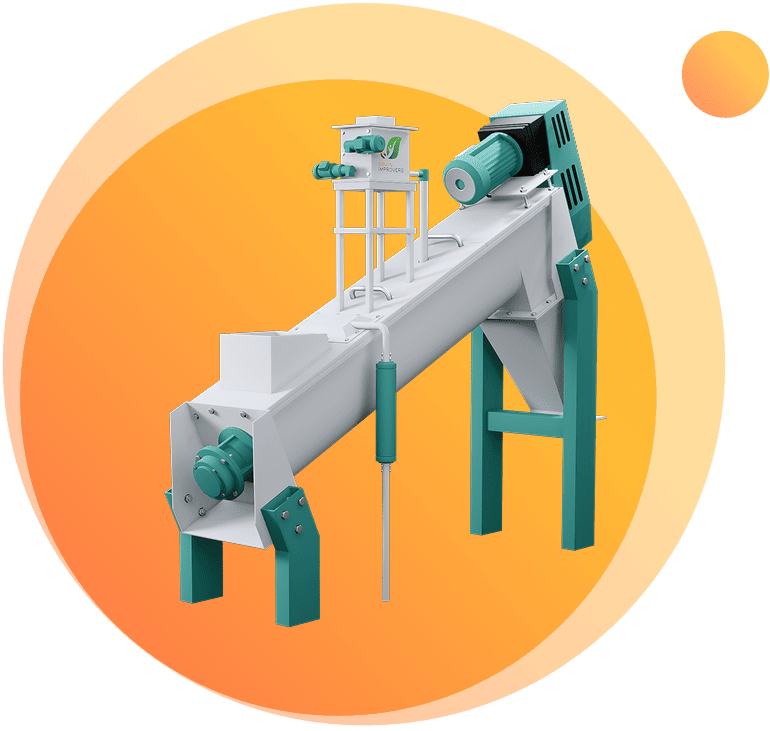

It is a dry powder, which is applied to damp grain with a basic micro-dosing. It is either installed to the moistening machine or to the distribution conveyor after the wetting process.

The grain with GRAIN IMPROVERS goes to the conditioning bunker for 8+ hours where the enzymes break the bond between shells and endosperm.

No change of equipment required

No drastic change in production process required

From a leading French factory with the highest purity and no by-products

Safety

Natural

Clean label

Health Certificate

Halal