Exploring Enzyme-Assisted Micronization of Whole Wheat

A single conversation at the 8th Whole Grain Summit sparked a promising collaboration between the GRAIN IMPROVERS team and engineers from Librixer, a company specializing in innovative micronization technology, which is suitable but not limited to whole grain processing.

Librixer’s experimental milling system offered an ideal opportunity to test how GRAIN IMPROVERS’ enzyme complexes interact with grain structure during micronization. Our enzyme solutions are designed to gently remove contaminated outer grain layers without discarding the nutritious subaleurone layer.

Together, we launched a joint experiment to investigate the impact of enzyme treatment prior to micronization.

Objective

To evaluate the structural behavior of wheat when enzymes are applied before micronization. Specifically, we aimed to observe the effects on grain composition, bran structure, and flour yield.

Methodology

The experiment was conducted at Librixer’s Test Center and laboratory in Sweden using cleaned winter wheat. Two test batches of 10 kg each were prepared:

- Control: standard tempering with water

- Test: tempering with water and 2 g of GRAIN IMPROVERS SMART enzyme per sample

Both batches underwent a 20-hour fermentation period before being micronized in one single pass under identical settings. Evaluation techniques included screening, particle size distribution (PSD) analysis, and scanning electron microscopy of bran particles.

Key Findings

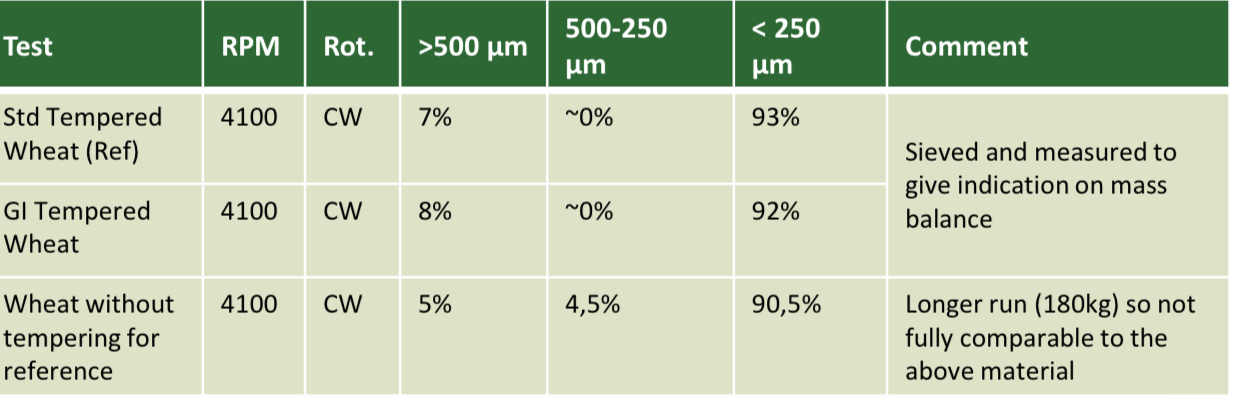

- Particle Distribution

Sieve analysis revealed a minor but consistent increase in larger particle fractions (>500 μm):

- 7% in the control sample

- 8% in the enzyme-treated sample

Although the increase was marginal, even small differences in pilot-scale conditions may indicate fundamental structural shifts. The proportion of fine flour particles remained unchanged with more than 90% below 125 µm, demonstrating that the enzyme treatment did not hinder the micronization process.

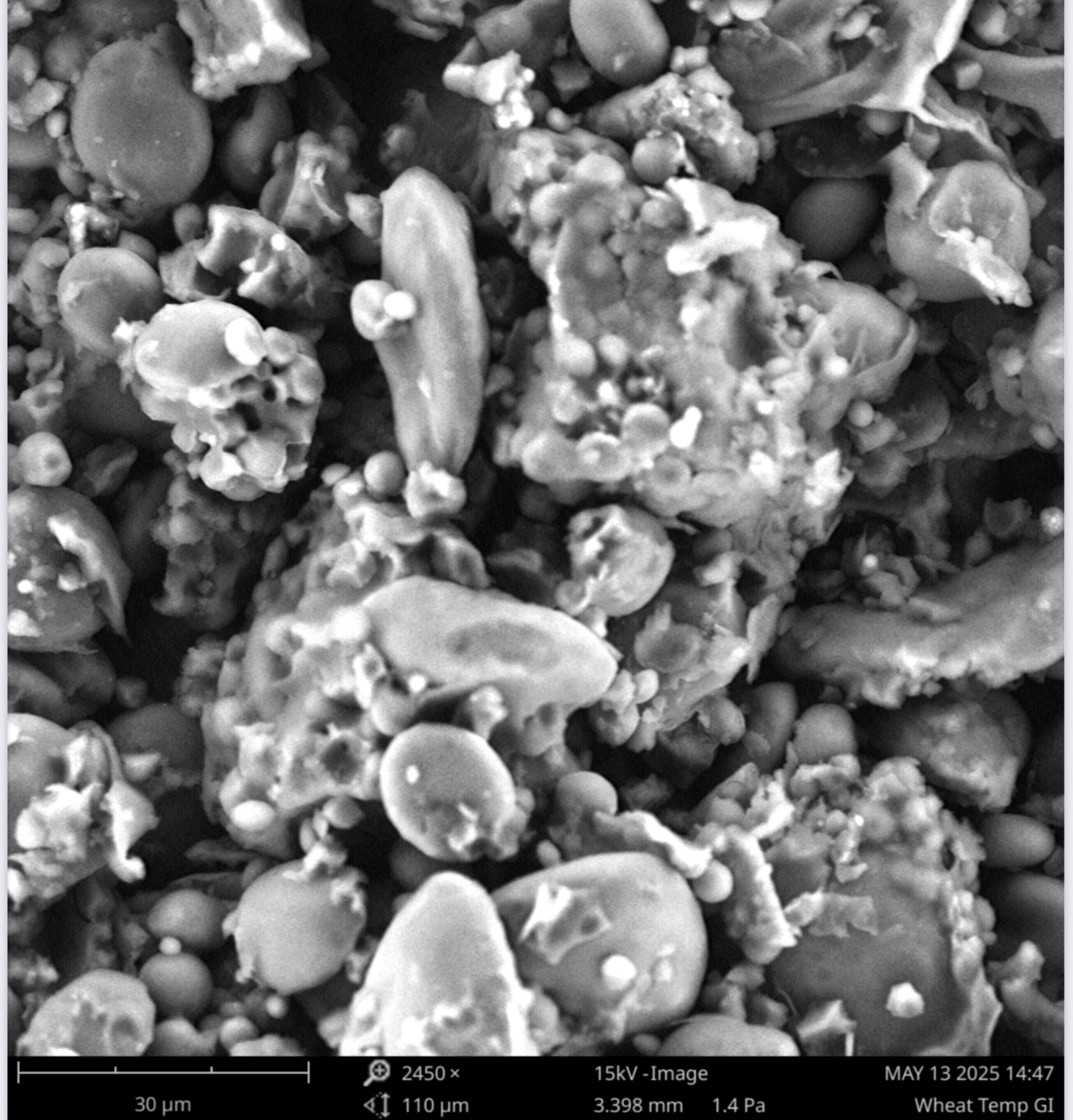

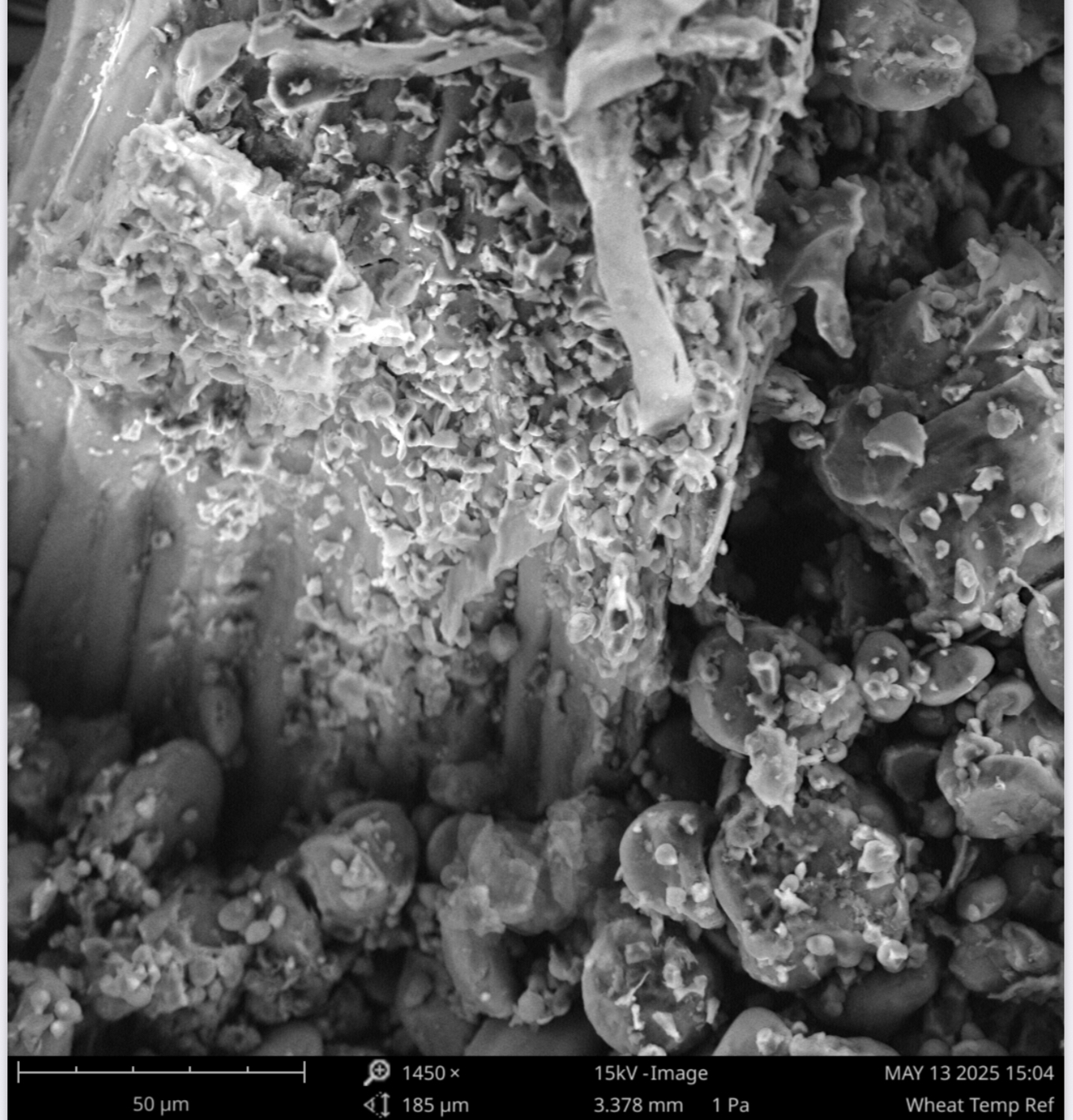

- Microstructural Changes

Electron microscopy showed clear differentiation between the samples:

- In the control sample, bran particles retained a dense subaleurone layer.

- In the enzyme-treated sample, this layer was absent, resulting in smoother, cleaner bran particles.

These results suggest that enzymatic treatment:

- Weakens the inter-layer bonding in wheat kernels

- Facilitates husk separation

- Minimizes nutrient loss, particularly proteins and B vitamins concentrated in the subaleurone layer

Significance

The observed changes carry several benefits:

- Improved Bran Separation: Larger bran fractions are easier to separate and less likely to contaminate the flour

- Enhanced Nutritional Yield: Cleaner separation allows more nutrients to remain in the flour rather than being discarded

- Process Compatibility: Enzymes support the milling process without negative impact, potentially enhancing protein extraction and the overall nutritional profile of the final product

Next Steps

We plan to expand our research with additional testing on:

- Baking performance

- Nutritional composition

- Water absorption properties

- Comprehensive bran analysis

If you are interested in exploring enzyme-assisted micronization at your milling facility, we welcome your collaboration. Together, we can continue improving the quality and sustainability of whole grain flour production.